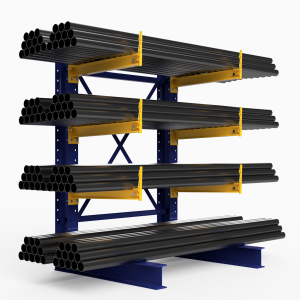

Cantilever Racking: The Ultimate Guide to Industrial Pipe Rack Storage

In the bustling world of industrial storage, finding the right solution for long, bulky items like pipes can be a challenge. Enter cantilever racking – a versatile storage system that has revolutionized how businesses handle industrial pipe rack storage. This blog post delves into the world of cantilever racking specifically designed for pipe storage, providing insights into its benefits, applications, and much more. Whether you’re a warehouse manager in Texas or an industrial designer looking for efficient storage solutions, this guide is tailored for you. Let’s explore how pipe rack systems can transform your storage strategy.

What Is a Cantilever Pipe Rack?

A cantilever pipe rack is a type of storage rack specifically engineered for long, heavy, or oddly-shaped items like pipes. Unlike traditional racking systems that rely on vertical supports at each end, cantilever racking uses horizontal arms extending from a single vertical column, allowing for easy access to stored items from the front. This design is particularly beneficial for industrial pipe rack storage because it eliminates the need for aisles between rows of racks, maximizing space efficiency.

How Cantilever Racks Work

- Structure: Consists of vertical columns with cantilever arms extending outward.

- Load Bearing: Arms support the weight of pipes, distributing it evenly across the column.

- Accessibility: Pipes can be loaded and unloaded from the front, simplifying logistics.

Top Benefits of Cantilever Racks for Pipe Storage

- Space Efficiency: By eliminating the need for front posts, these racks allow for full utilization of space, which is crucial in crowded warehouses.

- Ease of Access: Loading and unloading pipes is straightforward, reducing labor time and potential damage.

- Flexibility: Adjustable arms mean you can store pipes of varying lengths without modifying the rack structure.

- Durability: Made from high-quality steel, these racks can handle the weight and wear of heavy pipes over time.

Applications of Cantilever Pipe Racks

- Manufacturing: Ideal for storing raw materials like steel pipes before processing.

- Construction: Perfect for organizing long construction materials like metal pipes or tubes.

- Retail: For storing long retail items like carpet rolls or lumber in home improvement stores.

Cantilever Pipe Rack vs. Other Storage Solutions

- Versatility: Unlike pallet racks, cantilever racks can store items that are too long or irregularly shaped for standard pallets.

- Space Utilization: They outperform traditional shelving by providing unobstructed access and better space utilization.

- Load Handling: Cantilever systems can handle heavier loads per arm than many alternatives, reducing the need for multiple storage units.

Cantilever Pipe Rack vs. Other Storage Solutions

- Versatility: Unlike pallet racks, cantilever racks can store items that are too long or irregularly shaped for standard pallets.

- Space Utilization: They outperform traditional shelving by providing unobstructed access and better space utilization.

- Load Handling: Cantilever systems can handle heavier loads per arm than many alternatives, reducing the need for multiple storage units.

Types of Cantilever Racks for Pipe Storage

- Single-Sided: Best for wall placement, allowing access from one side.

- Double-Sided: Maximizes space by allowing access from both sides, ideal for the center of a warehouse.

- Light Duty: Suitable for lighter pipes or less frequent access.

- Heavy Duty: Designed for industrial environments with heavy, frequent use.

Designing a Warehouse Layout with Cantilever Pipe Racks

- Space Planning: Consider the flow of goods. Place racks where they can be easily accessed by forklifts or manually, depending on your operation.

- Load Consideration: Ensure the floor can support the weight of the loaded racks.

- Aisle Width: Keep aisles wide enough for safe maneuvering but narrow enough to maximize storage space.

Are you looking for an Industrial Pipe Rack Storage System?

Contact us today to explore our inventory and find the perfect solution for your storage needs.